Centre of Advanced Electron and Photonic Optics

The Centre of Advanced Electron and Photonic Optics TN02000020 (CAEPO) builds on the previous CEPO, which was awarded by the Technology Agency of the Czech Republic for its high contribution to society and economy in the PARTNERSHIP category.

The Centre brings together key academic and industrial players in The Czech Republic involved in research of electron, photon, and quantum technologies. CAEPO activities will enhance research excellence, application relevance of academic partners and knowledge transfer to industrial partners focusing on electron and light microscopy and spectroscopy, advanced lasers and their applications, opto-fibre sensors and probes, micro and nanostructured surfaces and optical elements, ultrasensitive detection at the edge of physical principles, ultra-precise production metrology, and development of sophisticated elements and systems. This synergistic cooperation shifts the level of added value of CAEPO industrial partner outputs, brings 2/3 of them closer to and keeps 1/3 at level of world leaders.

Participants:

Academic and research

- Institute of Scientific Instruments of the Czech Academy of Sciences

- Czech Technical University in Prague, Faculty of Mechanical Engineering and Faculty of Civil Engineering

- Palacký University Olomouc, Faculty of Science

- Institute of plasma physics, CAS / TOPTEC

- Brno University of Technology / CEITEC

- Biology Centre CAS

- Institute of Physics of the Czech Academy of Sciences

- Masaryk University / CEITEC

- The Institute of Photonics and Electronics, CAS

- Institute of Macromolecular Chemistry, CAS

- Institute of Molecular Genetics, CAS

Industrial Partners

- Meopta s.r.o.

- Compo Tech PLUS, spol. s r. o.

- TechSoft Engineering, spol. s r.o.

- CRYTUR, spol. s r.o.

- Thermo Fisher Scientific Brno s.r.o.

- IQS Group s.r.o.

- PSI (Photon Systems Instruments), spol. s r.o.

- MESING, spol. s r.o.

- NenoVision s.r.o.

- NETWORK GROUP, s.r.o.

The Faculty of Mechanical Engineering CTU in Prague has participated in the subproject "Advanced Design of Opto-Mechanical Systems". This subproject focuses on the design of diffraction-limited optical assemblies with advanced mechanical design and submicrometer precision positioning of optical components. The activities are built on the topics developed in the previous CEPO project. We are developing methods for simulations of optical and mechanical components (parasitic stress in optics, prediction of aberrations from temperature, vibrational behaviour of assemblies). Other activities focus on stress-free mounting of optics, coupling of optics to mechanics by soldering, high-precision positioning, automation of alignment, reduction of vibration effects, and application of composite materials in the support structures of opto-mechanical assemblies. All activities of the subproject are aimed at developing mask-less lithography, inspection in the DUV (Deep Ultra-Violet) spectra region, and advanced packaging in semiconductor industry.

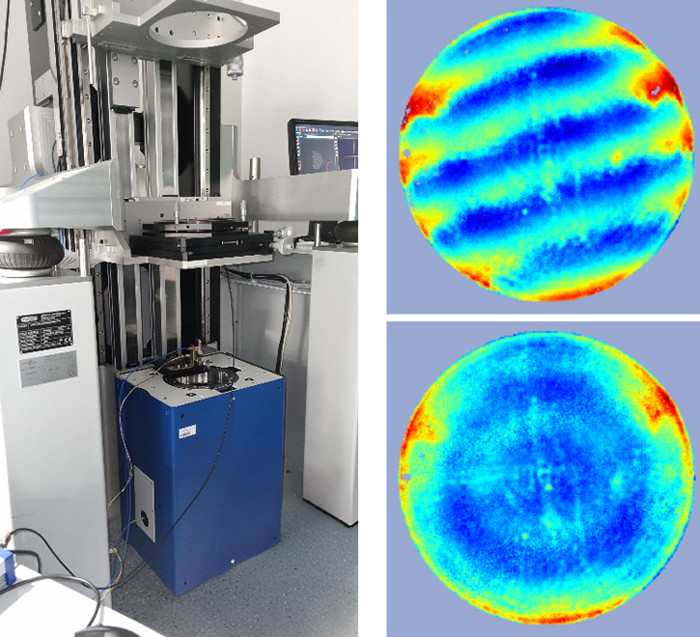

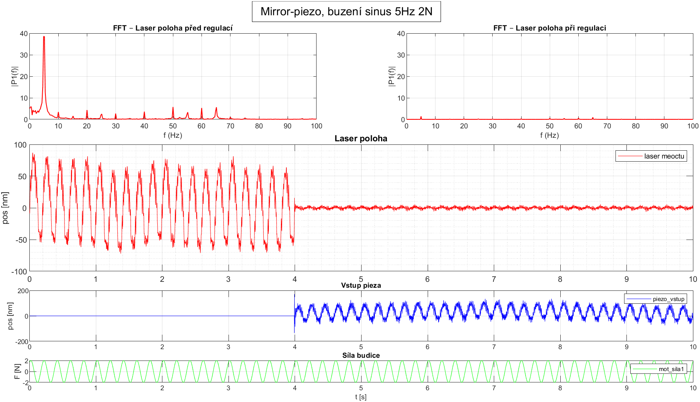

The Faculty of Mechanical Engineering of CTU in Prague has made significant contributions to the field, including the Utility Model "A feedback system for the active compensation of vibrations of Twyman-Green interferometer." This utility model has the potential to significantly reduce vibration effects that often complicate interferometric measurements and the subsequent reconstruction of the wavefront (Fig. 1). We believe that this utility model will serve as the foundation for future work on implementing a functional sample. The initial results and the verification of the principle of active feedback compensation will indicate the considerable potential of this technology.

Fig. 1: Twyman-Green Interferometer (TGI), Wavefront before/after active feedback vibration compensation, Measurements of

the TGI system behaviour without and with active vibration compensation.

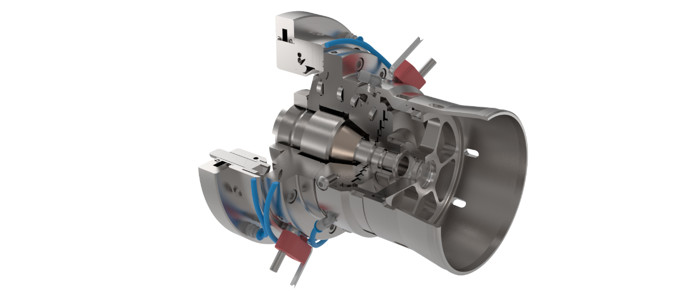

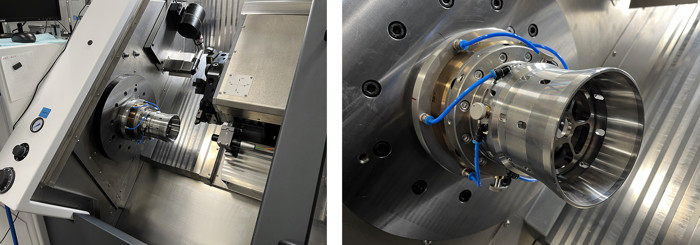

Another significant outcome is the realisation of the functional sample "2DOF Rotary Tilting Adjustment Fixture" in cooperation with the RCMT CTU in Prague. This is a new generation of centric turning head (Figs. 2 and 3), which allows us to maintain the achieved positioning accuracy of the machined lens cells centring to achieve decentre, axial position under micrometre range and lens tilt in mechanical cells were necessary for the most demanding industrial, resp. semiconductor application. Subsequent to this functional sample, we will focus on automation and algorithmization of positioning to enhance the efficiency of the lens cells' positioning process while satisfying the strict requirements for both tilt and decenter lenses in the tightest optical assemblies for lithography, inspection and advanced packaging.

Fig. 2: Centering turning head designed towards very high lens-cell precision machining.

Fig. 3: Final functional sample assembly installed against the collimator for centric turning.

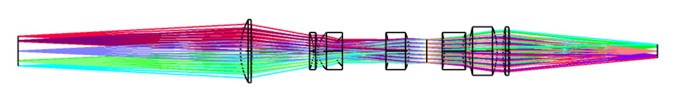

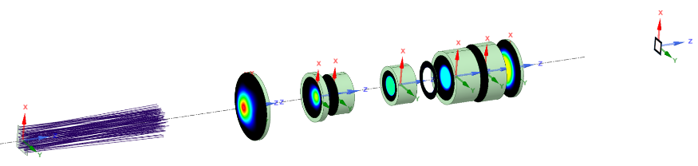

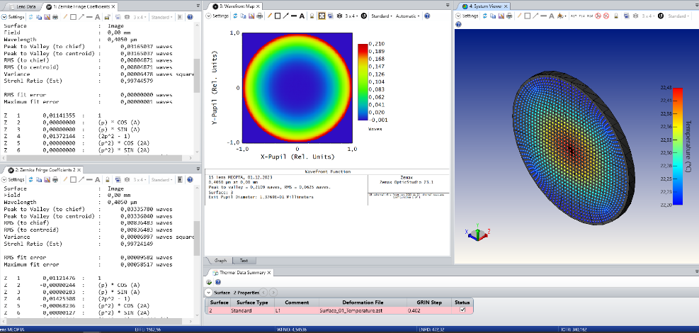

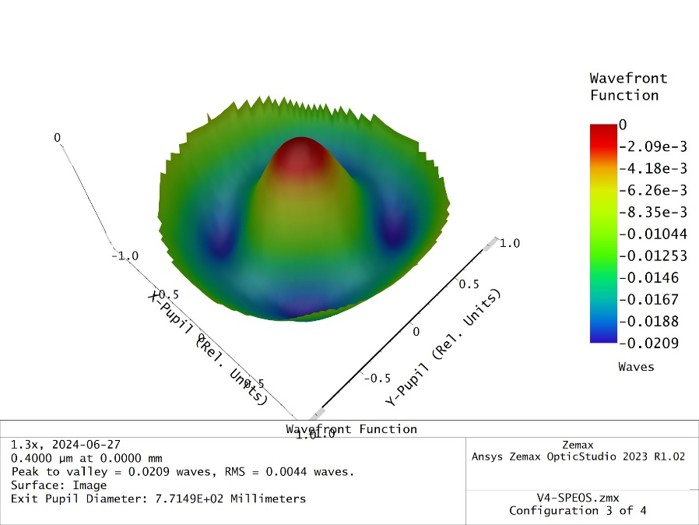

As part of our project, "Advanced Design of Opto-Mechanical Systems" we are streamlining the optical system design process. Our goal is to predict the operational behaviour of optomechanical systems subjected to high power, inhomogeneous temperature distribution in the lens, and other effects at an early stage of optical design. This advanced approach to optical design begins with sequential tracing, followed by physical optical propagation through the system, obtaining strain and temperature distributions by FEM or other approaches, and evaluating the wavefront error of the power-loaded system (Fig. 4).). The outputs of this analysis sequence are used by optical designers to react and modify the final optical design.

Fig. 4: Demonstration of the use of FEM simulations for the design of optomechanical systems.

The Faculty of Mechanical Engineering is engaged in additional project activities, including the development of mechanisms with the potential for sub-micrometre positioning of optics, low-stress mounting of optical elements, and AI powered heuristics over databases of known optical designs.

We expect that the results will be used by our industrial partners in the optical industry in the development, production, and metrology of components, assemblies, and complete systems that bring high added value and reach new levels of competitiveness.

The aim of the subproject is to increase the research competence and application relevance of the academic partners orientated towards enhancing knowledge transfer to industrial partners. This synergistic cooperation will advance the current level of development and production of optical systems and increase the added value of the industrial partners' products.

Faculty of Mechanical Engineering CTU in Prague academic and research partners:

Acknowledgements to our industrial partners:

Meopta s.r.o., Compo Tech PLUS, spol. s r. o. and TechSoft Engineering, spol. s r.o.

![]()

![]()

![]()

![[design/2014/cvut-logo-en-white.png]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-en-white.png)

![[design/2014/cvut-logo-en-print.jpg]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-en-print.jpg)