Quality control of weld joints of the aluminum alloy engine cover

Quality control of weld joints (engine cover), where weld joint defects were detected. The aim of the expertise was to determine

the cause of these defects. The engine cover was made from two different aluminum alloys. The cover sheet was made from aluminum

alloy EN AW 7022, and the reinforcements were made from aluminum alloy EN AW 6082. The MIG welding method with filler material

type EN AW 5356 was used for welding. The part is intended for a racing special – supplied by Škoda Motorsport.

Fig. 1 – Supplied engine cover part – view of the inner side where the reinforcements are welded

For evaluation, the weldability of the used aluminum alloys was described, and visual and capillary tests were performed. In selected parts, metallographic examination of the macrostructure was carried out.

The visual inspection of the supplied weldment, focusing on weld joint defects, was conducted in accordance with ČSN EN ISO 17637 and defect evaluation according to ČSN EN ISO 10042 - quality level D. The fracture locations (cracks) and typical defect types were examined in more detail to determine the cause of the failure.

In this test, characteristic damages were selected and further assessed using metallographic analysis.

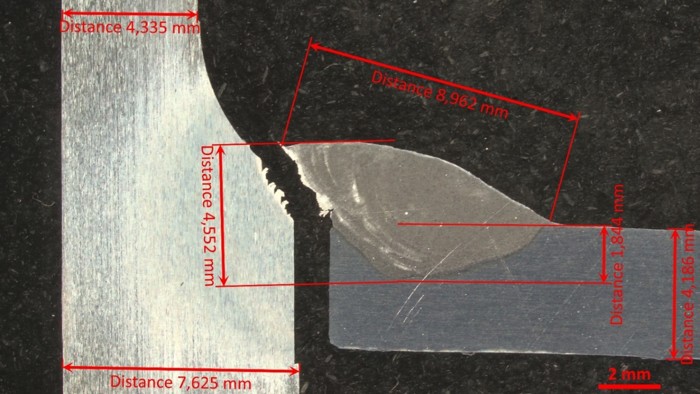

![Crack in the weld joint [pracoviste/12133/projekty-skoda/weld-joints/image3.jpeg]](https://fs.cvut.cz/content/images/pracoviste/12133/projekty-skoda/weld-joints/image3.jpeg)

Fig. 2 – Crack in the weld joint

Furthermore, sampling locations for macrostructure testing were identified.

Fig. 3 – Example of failure at the weld joint

A number of unacceptable defects were found on the supplied part through visual inspection, particularly a large number of

cracks. It was confirmed that these cracks occurred during the operational load of the weldment (engine cover), but they indicate

an unsuitable condition of the weldment (stemming from its production).

Furthermore, the impact of the chosen material combination - heterogeneous weld - specifically the negative contribution of the EN AW 7022 alloy (sheet) and especially the quality of the weld joints was analyzed, and corrective measures for production with a greater emphasis on the quality of the weld joints were recommended.

In collaboration with:

Contact:

prof. Dr. Ing. Antonín Kříž

Department of Manufacturing Technology FME CTU in Prague

E-mail: antonin.kriz@cvut.cz

Phone: +420 737 163 433

![[design/2014/cvut-logo-en-white.png]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-en-white.png)

![[design/2014/cvut-logo-en-print.jpg]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-en-print.jpg)