LRI-AAST: L1 and L2 laboratory DACS systems

| Lab | Equipment |

|---|---|

| L1 - DYNO and CORE test cells L2 - PROP1 and PROP2 test cells |

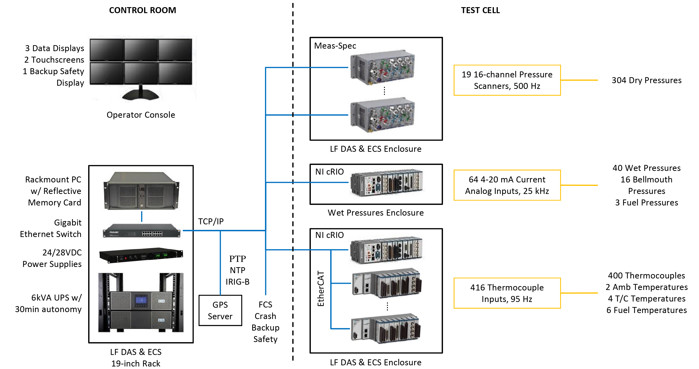

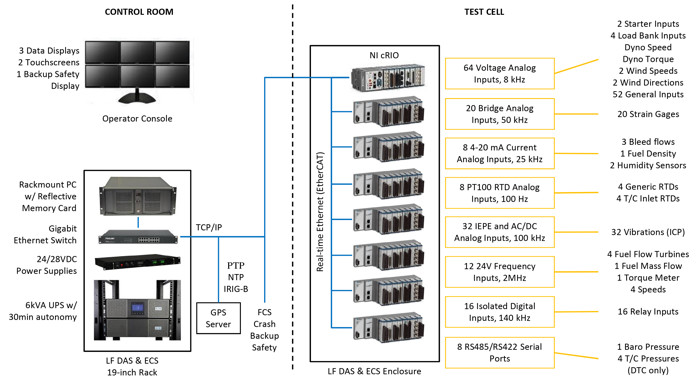

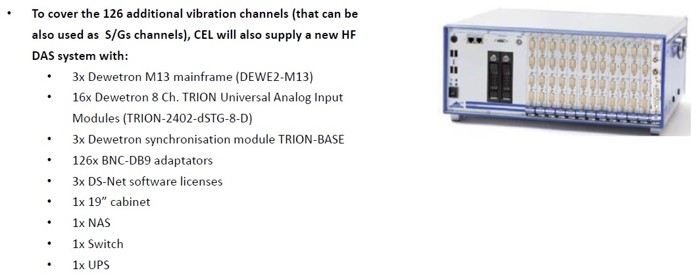

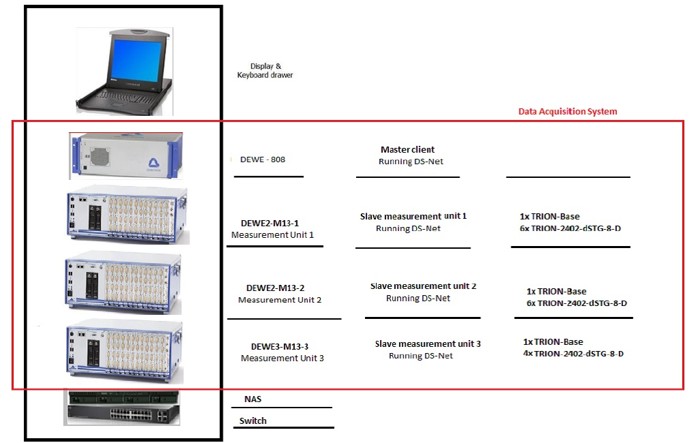

Data Acquisiton System The test cells are equipped with large DAS that can be grouped together for more channels if necessary |

| Measurement | No | Range | Notes |

|---|---|---|---|

| Fuel Flow* | 2 | 0-800 pph | To be installed on facility piping. From fuel tank to engine FMU. Redundant turbine flowmeters. The flowmeters should be volumetric; the mass calculation must be done in the LF system real time calculation. |

| Fuel Flow* | 2 | 0-2500 pph | To be installed on facility piping. Motive Flow From FMU recirculating. Redundant turbine flowmeters. The flowmeters should be volumetric; the mass calculation must be done in the LF system real time calculation. |

| Fuel Flow* | 1 | 0-1 kg/dm3 | Densimeter on facility piping for gr from volume to mass |

| Fuel Flow* | 1 | 0-800 pph | Coriolis fuel flowmeter to be used for check consistency. |

| Fuel Pressures* | 3 | 0 - 70 psig | From facility tank to FMU and motive flow from FMU to recirculation. |

| Fuel temperature* | 6 | Ambient Temperature | To be installed on facility piping near each flowmeter and before FMU |

| Time (GPS Synchronization system) |

1 | N/A | Needed to synchronize all systems. At least 1O H z is required. |

| lnlet Temperature | 4 | Ambient Temperature | To be installed on test cell inlet |

| Test Cell Pressures | 4 | Ambient Pressure | Front/Rear test cell pressure. Probes to be included. |

| Test Cell Temperatures | 4 | Ambient Temperature | Front/Rear test cell temperatures. Probes to be included. |

| Engine Torque (Dyno Test Cell) |

1 | Lb*ft | lnline torquemeter |

| Environment | 1 | Ambient Humidity, Temperature, Pressure |

Weather station to be installed outside test cell. |

| Test Cell lnlet Temperature | 4 | Ambient Temperature |

4 RTDs on test cell inlet |

| Airflow | 1 | Engine lnlet Airflow, Dyno Test Cell | Ref. dyno test cell RFQ and below notes about standard instrumentation. |

| Measurement | Type of sensor | Minimum Number of Channels |

|---|---|---|

| Temperature | Thermocouples | 180 Type E 180 Type K 40 Type T Total: 400 |

| Pressure | Pressure Scanner (see below for proposed ranges) | 300 |

| Pressure | Transducers (individual 28VDC power supplies shall be provided, see below for proposed range) | 40 |

| Vibrations | ICP Accelerometers (low noise cable) | 32 |

| Clearance | Acquired on average and min signal in Vdc | 15 |

| On/off | Relays (I/O) | 16 |

| General inputs | Vdc/4-20 mA | 64 |

| Speed | Generic frequency | 8 |

| FTS | Reflective Memory, fiber optics interface | n/a |

| Control Systems inputs | RS232, Ethernet. Facility control system, Dyno control system. | n/a |

| Force | Static Strain Gage | 20 per site |

| Temperature | Generic RTDs | 4 |

| Air Flow | Orifice or equivalent | 3 bleeds |

| Starter | Voltage and Amperes value to be acquired from the starter power generator | 2 |

![[design/2014/cvut-logo-en-blue.png]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-en-blue.png)

![[design/2014/cvut-logo-print.jpg]](https://fs.cvut.cz/content/images/design/2014/cvut-logo-print.jpg)